Recently, the market has been out of stock of 9494 or 3180 fluoroethylene propylene (FEP), which has attracted attention to FEP materials again. The fluoroethylene propylene (FEP) high-speed transmission cable is a cable that connects communication equipment. It has the advantages of low attenuation, low delay, low loss, energy saving and environmental protection. It is widely used in high-speed communication places such as data centers and high-performance computer connections. With the improvement of high-speed transmission requirements, the environments faced by high-speed transmission cables are also different. Different occasions have different requirements for the tear resistance, temperature resistance and chemical corrosion resistance of cables. In addition to having good electrical properties, cables are also required to have good mechanical properties and chemical stability. Polyfluoroethylene propylene (FEP) is made by copolymerization of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP). It has excellent chemical resistance, high temperature resistance, weather aging resistance and cracking resistance, making it a high-quality choice for cable protective layer, and is deeply loved by many fields such as aerospace, electronics industry and petrochemical industry.

Compared with polytetrafluoroethylene (PTFE), trifluoromethyl is introduced into the side chain of FEP, which is equivalent to replacing some fluorine atoms with trifluoromethyl. The introduction of trifluoromethyl destroys the crystallinity of the chain and reduces the viscosity, so that FEP can be processed by an extruder, effectively improving the processing performance.

Advantages of FEP material in insulating core wire:

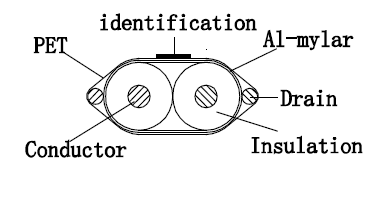

The insulating medium should also be uniform as required by the conductor, and in order to obtain a lower dielectric constant s and dielectric loss tangent value, SAS series cables generally use PP insulation or FEP insulation:

★ FEP has very low dielectric constant and dielectric loss, and the insulating core wire has the characteristics of low attenuation and stable signal, and is used in high and low frequency fields.

★ FEP has excellent temperature resistance, with a continuous working temperature range of -85-200℃, and a short-term use temperature of -200-260℃.

★ FEP has excellent flame retardant properties, with an oxygen index greater than 95, and is almost non-flammable. Used as a protective layer for high-speed transmission cables, it has good flame retardancy, a small flame diffusion range when burning, and produces less smoke

★FEP has good mechanical properties. Even after a lot of twisting and bending, the insulated core wire can still maintain good integrity, which can protect the internal wire from contact with the outside and avoid wire corrosion or leakage short circuit.

★FEP insulated core wire has good welding processability. It is not easy to shrink during the welding process of the cable and connector, and maintains good electrical performance stability.

★FEP can be used to make insulated core wires through extrusion technology, which can produce extremely fine wires with stable molding, stable wire diameter and not easy to deform.