FEP Cable is an abbreviation for Fluorinated Ethylene Propylene. It has many applications. There are several advantages to using FEP cable compared to other types of cables. Let’s learn more about some of these uses and benefits, especially why FEP may be equal to or even better than polytetrafluoroethylene (PTFE).

FEP Cable-Fluorinated Ethylene Propylene’s Class 1 corrosion resistance is exactly the same as that of PTFE, and therefore also competitive with caustic agents. Its pure fluorocarbon structure and fluorination make it corrosion resistant. In particular, FEP coated cables are more resistant to detergents than PTFE.

Advantage #2 – FEP cable has a lower melting point than other cable materials, such as PTFE and PFA. The exact point hovers around 260°C (500°F).

FEP Cable Advantage #3 – From an electrical point of view, only PFA surpasses FEP. This means that the material has the highest dielectric strength. At the same time, FEP has a dissipation rate six times higher than PFA. The end result is that FEP can conduct nonlinear electrostatic fields better.

FEP Cable Advantage #4 – FEP has a slight advantage over PTFE in terms of flexibility, giving it a place in the mechanical space.

FEP Cable Advantage #5 – When cable leads are made from FEP, they exhibit excellent resistance to chemicals, fluids, aging, and ozone.

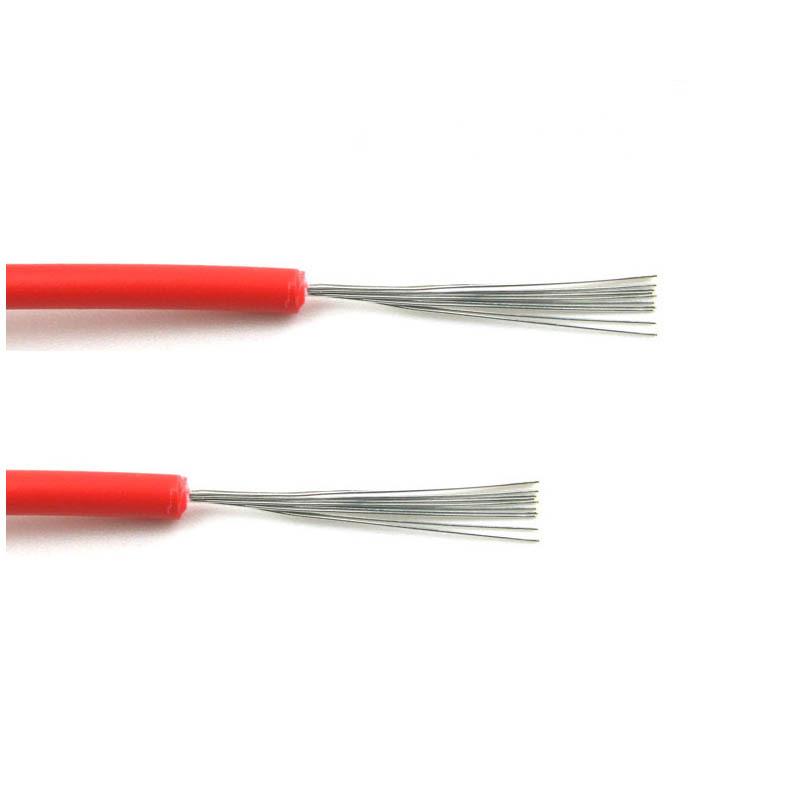

FEP Cable Advantage #6 – FEP allows for smaller diameters.

FEP Cable Advantage #7 – When the cable is designed to be torque-free, the memory typically found in right- or left-hand stranded cables is eliminated.

As you can imagine, the advantages of FEP cable make it a good choice for certain applications. Some of these include:

FEP Insulation/Cable Application #1: Wiring – Think electrical wires, coaxial cables, computer wiring, and wiring for connected technology equipment.

FEP Insulation/Cable Application #2: Aerospace – In this application, FEP insulation helps protect the mold during the curing process.

FEP Insulation/Cable Application #3: Labware and Tubing – The highly corrosive chemical processes that often occur in labs have many effects on plastic labware and tubing. FEP has excellent resistance to such attacks.

FEP Insulation/Cable Application #4: Industrial High Temperature Applications (e.g. glass plants, boiler locations, chemical processing plants, areas near steam pipes) - When multi-core cable is insulated and jacketed with polyvinyl fluoride, resistance to abrasion and mechanical abuse is maximized. Moisture and liquid damage is also mitigated.