When it comes to electrical applications and wiring, silicone wire stands out as a reliable and efficient choice. From its excellent thermal resistance to its flexibility and durability, silicone wire has become a popular option across various industries. This article delves into the many advantages and applications of silicone wire, shedding light on why it has gained such widespread recognition.

1. Superior Temperature Resistance

Silicone wire is renowned for its exceptional temperature resistance properties. Unlike regular PVC wires, which degrade under high temperatures, silicone wire can withstand extreme heat without losing its electrical conductivity or structural integrity. This unique attribute makes silicone wire ideal for applications that involve exposure to high temperatures, such as industrial heating equipment, furnace wiring, and electric motors.

2. Exceptional Flexibility

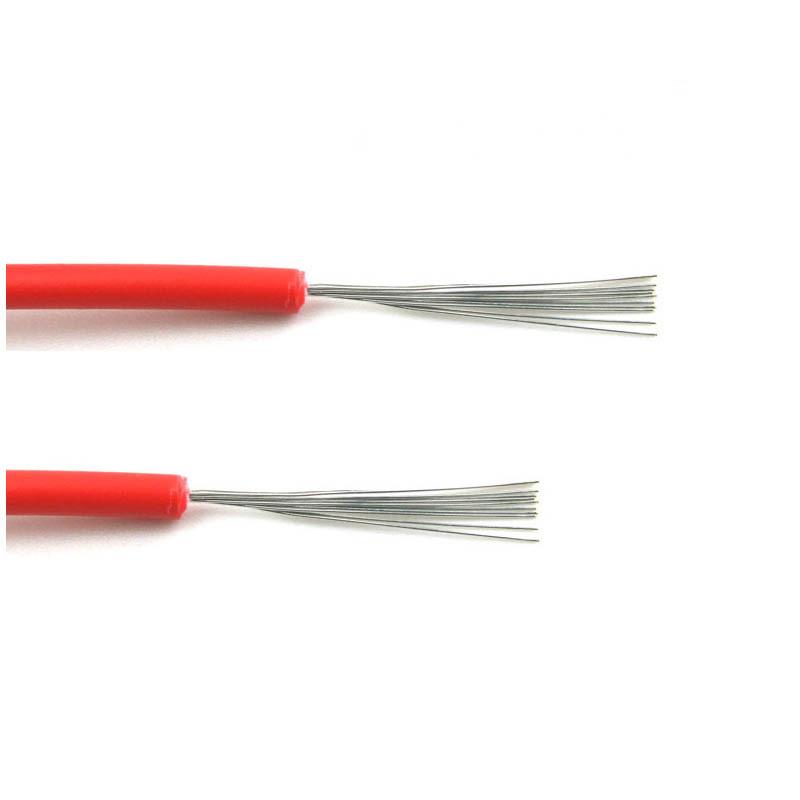

Flexibility is another key advantage of silicone wire. Its soft and pliable nature allows for easy bending and routing without compromising its performance. This flexibility makes silicone wire highly suitable for applications that require complex wiring setups or situations where wire movement is involved, such as robotics, automation systems, and aerospace industry.

3. Impressive Electrical Insulation

Electrical insulation is crucial when it comes to wire selection. Silicone wire offers superior dielectric strength, making it an excellent insulator. Its ability to prevent electrical leakage, combined with its resistance to moisture, chemicals, and ultraviolet radiation, makes it a reliable choice for various outdoor and indoor applications. Silicone wire is commonly used in industries like telecommunications, automotive, and renewable energy.

4. Chemical Resistance

Silicone wire exhibits remarkable resistance to chemicals and solvents, making it highly suitable for applications in chemically demanding environments or where exposure to liquids is common. The wire's protective silicone insulation ensures that it remains unaffected by oils, acids, alkaline solutions, and other corrosive substances. This makes silicone wire an optimal choice for chemical plants, laboratories, and medical equipment.

5. Easy Installation and Maintenance

Another advantage of silicone wire is its ease of installation and maintenance. The wire's flexibility allows for effortless routing and termination, reducing installation time and effort. Furthermore, silicone wire's durability and resistance to aging minimize the need for frequent replacements or repairs. This translates to reduced downtime and improved operational efficiency in industries that rely heavily on electrical systems.

Concluding Thoughts

Silicone wire's temperature resistance, flexibility, electrical insulation, chemical resistance, and ease of installation make it an all-around performer in various industries. Whether it is in high-temperature environments, chemically challenging applications, complex installations, or demanding electrical systems, silicone wire offers numerous benefits. So, when reliability and longevity are prioritized, silicone wire emerges as an excellent choice for powering tomorrow's technological advancements.