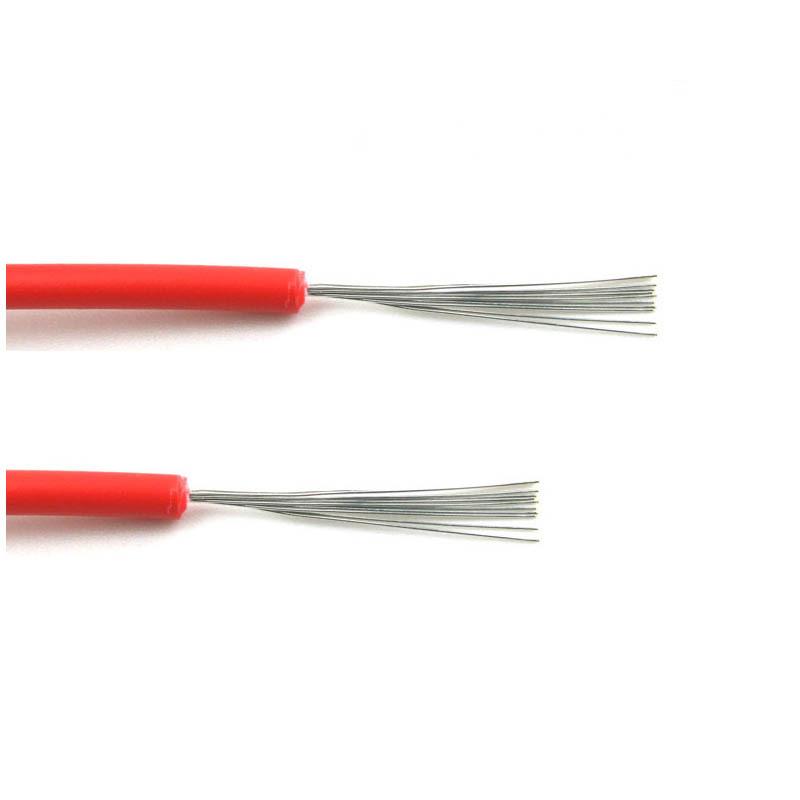

High-temperature wire applications require materials that can withstand extreme heat and maintain their integrity over time. Teflon, also known as polytetrafluoroethylene (PTFE), has emerged as a leading choice due to its exceptional thermal stability and low friction properties. With a deep understanding of these characteristics, Teflon offers an ideal solution for enhancing the durability of high-temperature wires.

1. Teflon's Exceptional Heat Resistance

Teflon is renowned for its remarkable heat resistance, making it an optimal choice for high-temperature wire coating. Its melting point of around 327°C (621°F) ensures that Teflon-coated wires can operate reliably in extreme conditions without compromising their integrity. This inherent heat resistance shields the wires from potential damage caused by excessive temperatures.

2. The Virtues of Low Friction in Wire Applications

In addition to its heat resistance, Teflon's low friction properties bring significant advantages to high-temperature wires. The smooth surface of Teflon reduces the coefficient of friction, allowing wires to move more freely without excessive resistance. This reduces wear and tear, minimizes the risk of damage, and extends the lifespan of high-temperature wires.

3. Teflon's Chemical Inertness

Another invaluable feature of Teflon in high-temperature wire applications is its exceptional chemical inertness. Teflon is highly resistant to corrosive substances, acids, and bases. This exceptional chemical resistance prevents wires from deteriorating or losing their functionality when exposed to harsh environments, ensuring long-term durability.

4. Insulation Superiority

Teflon coatings provide exceptional insulation for high-temperature wires. The high dielectric strength of Teflon prevents current leakage, ensuring reliable electrical insulation even at elevated temperatures. Teflon's insulation properties minimize the risk of short circuits, electrical failures, or compromised safety, thus preserving the durability and reliability of high-temperature wires.

5. Resistance to Environmental Factors

High-temperature wires often operate in demanding environments with exposure to moisture, UV radiation, and other environmental stressors. Teflon's resistance to these factors protects the underlying wires from degradation, maintaining their durability. Whether in extreme heat or harsh outdoor conditions, Teflon-coated wires exhibit exceptional longevity.

6. Flexibility and Durability

Flexibility is a crucial factor in high-temperature wire applications. Teflon coatings provide excellent flexibility without compromising durability. The coating remains intact even when wires are bent or exposed to mechanical stress, ensuring long-term performance and durability even in challenging installation scenarios.

Conclusion

Teflon's extraordinary heat resistance, low friction properties, chemical inertness, insulation superiority, resistance to environmental factors, and flexibility make it an irreplaceable material for ensuring the durability of high-temperature wires. By utilizing Teflon coatings, wire manufacturers can guarantee high-performance, long-lasting wires capable of withstanding the most challenging conditions.