Wires are the most common objects in our lives, but you can't underestimate these small wires. Without these wires, our electricity consumption becomes the biggest problem. At present, there are many kinds of wires we are exposed to, and Teflon wire is one of them. So, what is Teflon wire? It is said that it can run normally even if it is placed in water. Is this true? Let's take a look.

1. Teflon wire

Teflon wire is actually a kind of wire with fluoroplastic as the insulation layer. This kind of wire is also called fluoroplastic wire. Since fluoroplastic is also a kind of plastic, Teflon is also known as the "King of Plastics". The production process of Teflon wire is relatively simple. Many friends may be interested. Here is a brief introduction to its production process:

The first step is to put copper slag or copper-containing materials into the boiler, pump in extremely high pressure oxygen to make the temperature reach the boiling temperature of copper water, and obtain melted copper water;

The second step is to pour the copper water into the mold, wait for the mold to cool down after being immersed in water, and then perform temperature processing on it;

The third step is to remove the impurities in the molding module by electrolytic bath, and melt the copper plate again;

The fourth step is to pull the cooled pure copper water into a thicker copper strip, and then make the copper strip into a wire of appropriate thickness and size, and finally add a layer of Teflon insulation to the outer layer of the wire.

Fluoroplastic wire is currently used in the electronics industry, and can also be used as a temperature compensation wire. Moreover, many household appliances we usually use, such as air conditioners, rice cookers, microwave ovens, electric water bottles, etc., also often use fluoroplastic wires for internal wires.

2. Is Teflon wire good?

As the "king of plastics", Teflon cable is a very magical material in the eyes of many people. Therefore, many people will admire the wires made of Teflon. So, is this kind of wire really that good? Let's take a look at its advantages first.

① Non-stickiness

Teflon basically does not adhere to any substance. Fluoroplastic wire is a non-stick coating, and dust and stains are difficult to stick to the fluoroplastic wire.

② Heat resistance

It has very good heat resistance and low temperature resistance. It can be used continuously between 240℃~260℃, and it can also keep the wire stable and will not melt; in low temperature environment, the fluoroplastic wire will not become stiff and brittle.

③ Insolubility

It is insoluble in any organic solvent, including water, oil and other substances that we often deal with wires in life. This also means that the fluoroplastic wire has the characteristic of not absorbing moisture.

④ Wear resistance

Under the specified load, the fluoroplastic wire is not only non-adhesive, but also very wear-resistant; even under high load, it has good wear resistance.

⑤ Corrosion resistance

It will not be corroded by drugs and chemicals, and in the case of strong acidity and alkali, it can also ensure that the parts are protected from damage.

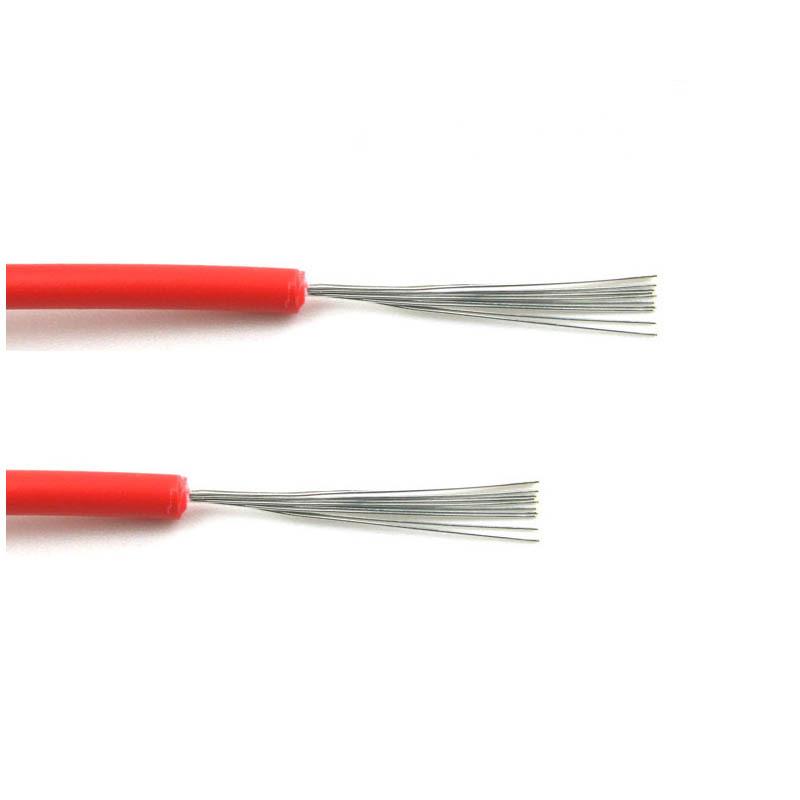

Teflon wire purchase guide. When choosing teflon insulated wire, many friends tend to choose low-priced wires in order to reduce the cost of wires. But in fact, wires are related to the safety of household electricity use. If the quality of wires is not up to standard, it may cause some hidden dangers in electricity use. So, how to choose fluoroplastic wires is the right way?See whether the product can provide 3C certification. Wire and cable products produced by regular manufacturers are all qualified for 3C certification issued by the state. Because the 3C certification mark is the greatest embodiment of safe products, to some extent, it can prove the quality of the product.See the thickness of the insulation layer of the product. Different types of wires have different thicknesses of insulation layers, all within a specified range of values. And the thickness of the insulation layer of high-quality wires is relatively uniform, facing the core material.See whether the wire core of the product meets the regulations. Regular wires are made through strict processes such as drawing, annealing, and twisting. The surface of the wire core is not only smooth and bright, but also should be burr-free, tough, and not easy to break.

Can Teflon wires be put in water? Plastics are basically waterproof, and teflon insulated wire, as the king of plastics, also has advantages in water release. In the previous introduction, we also know that fluoroplastic wires have good waterproof and corrosion resistance. So, can Teflon wires really be used in water? Teflon is a material that will not blend with other organic solvents, including water. Therefore, Teflon wires will not touch the water when placed in water. In other words, fluoroplastic wires can enter water. But it should be noted that even if fluoroplastic wires have good waterproof properties and can run in water. But no one can guarantee when the wires will age or be damaged. If the wires are placed in water for a long time, it may also cause some safety hazards, such as leakage.

In short, if you don’t have to put the teflon cables in water, you should put them in a dry place as much as possible. If the wire installation environment really cannot avoid water erosion, you can put the wires in the wire tube first, and then carry out construction, which can at least extend the service life of the teflon wires.