Teflon insulated wires are essential components used in various industries due to their exceptional properties such as high temperature resistance, chemical inertness, and electrical insulation. The manufacturing process of teflon insulated wires involves several intricate steps to ensure the quality and reliability of the final product. In this article, we will delve into the detailed manufacturing process of Teflon insulated wires in factories.

Raw Material Preparation:

The manufacturing process begins with the preparation of raw materials. The primary material used for teflon wires is polytetrafluoroethylene (PTFE), commonly known as Teflon. PTFE resin is sourced from reputable suppliers and undergoes stringent quality checks to ensure purity and consistency. Additionally, other materials such as copper or aluminum conductors, insulating tapes, and protective coatings are also prepared and inspected for quality.

Extrusion:

Once the raw materials are prepared, the extrusion process begins. In this step, the PTFE resin is melted and extruded onto the conductor to form the insulation layer. The extrusion process is carefully controlled to maintain precise temperature and pressure conditions, ensuring uniformity and consistency of the insulation thickness. The insulated conductor passes through cooling chambers to solidify the insulation layer before further processing.

Sintering:

After extrusion, the insulated conductor undergoes a sintering process to enhance the properties of the PTFE insulation. Sintering involves heating the insulated conductor to a specific temperature below the melting point of PTFE, allowing the resin particles to fuse together and form a dense, durable insulation layer. This process improves the mechanical strength, thermal stability, and chemical resistance of the insulation, making it suitable for demanding applications.

Stranding and Braiding:

Once the insulation is sintered, the insulated conductors may undergo stranding or braiding processes to enhance flexibility and strength. Stranding involves twisting multiple insulated conductors together to create a flexible and robust cable structure. Braiding may be applied for additional mechanical protection or shielding against electromagnetic interference (EMI). These processes are tailored to meet specific requirements and performance standards for different applications.

Jacketing:

After stranding or braiding, the insulated conductors are jacketed with an outer layer of protective material. The jacketing material can vary depending on the application and environmental conditions. Common jacketing materials include PVC (polyvinyl chloride), TPU (thermoplastic polyurethane), or silicone rubber. The jacketing process provides additional mechanical protection, abrasion resistance, and insulation against external factors such as moisture, chemicals, and physical damage.

Testing and Quality Assurance:

Throughout the manufacturing process, rigorous testing and quality assurance measures are implemented to ensure the performance and reliability of the Teflon insulated wires. Various tests, such as electrical conductivity, insulation resistance, voltage withstand, and dimensional checks, are conducted according to industry standards and specifications. Any non-conforming products are identified and rectified to maintain the highest quality standards.

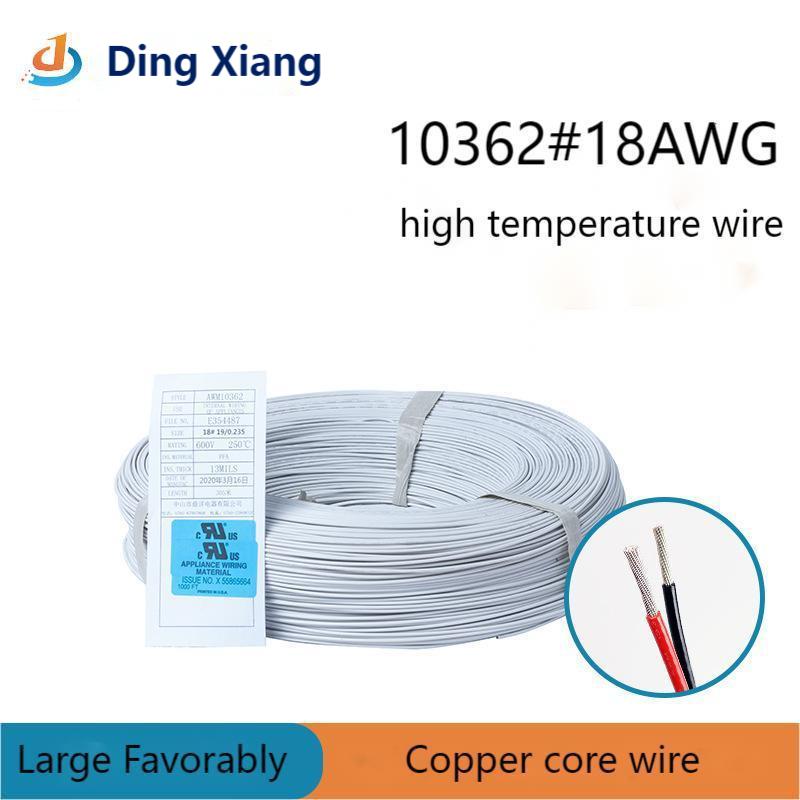

Packaging and Shipping:

Once the Teflon insulated wires pass all quality checks, they are packaged according to customer requirements and industry standards. Proper packaging ensures the protection of the products during storage and transportation. The packaged wires are then shipped to customers or distribution centers, ready for use in a wide range of applications across industries such as aerospace, automotive, electronics, and medical.

The manufacturing process of Teflon insulated wires in factories involves a series of precise and controlled steps to produce high-quality and reliable products. From raw material preparation to extrusion, sintering, stranding, jacketing, testing, and packaging, each stage is carefully executed to ensure the performance, durability, and safety of the final product. With advanced technologies and stringent quality assurance measures, Teflon insulated wire manufacturers continue to innovate and deliver solutions that meet the evolving needs of industries worldwide.