Understanding the Basics of PTFE Wire

PTFE wire refers to a type of electrical wire that utilizes PTFE (Polytetrafluoroethylene) as its insulation material. PTFE is a high-performance fluoropolymer known for its excellent electrical properties, chemical resistance, and thermal stability. It is commonly used in various industries where high temperature, harsh environments, and reliability are of utmost importance.

Properties and Benefits of PTFE Wire

PTFE wire offers several key advantages over other types of wire. Firstly, its exceptional temperature resistance allows it to operate in extreme hot or cold conditions, ranging from -200°C to 260°C. This makes it suitable for applications in aerospace, automotive, and oil & gas industries.

Another significant property of PTFE wire is its excellent electrical insulation capabilities. It exhibits low dielectric constant and dissipation factors, making it ideal for high-frequency applications, such as in telecommunications and electronic devices where signal integrity is crucial.

Furthermore, PTFE wire has outstanding chemical resistance, as it is unaffected by most chemicals, solvents, and fuels. This quality ensures the wire's longevity even in challenging environments, such as chemical plants and laboratories.

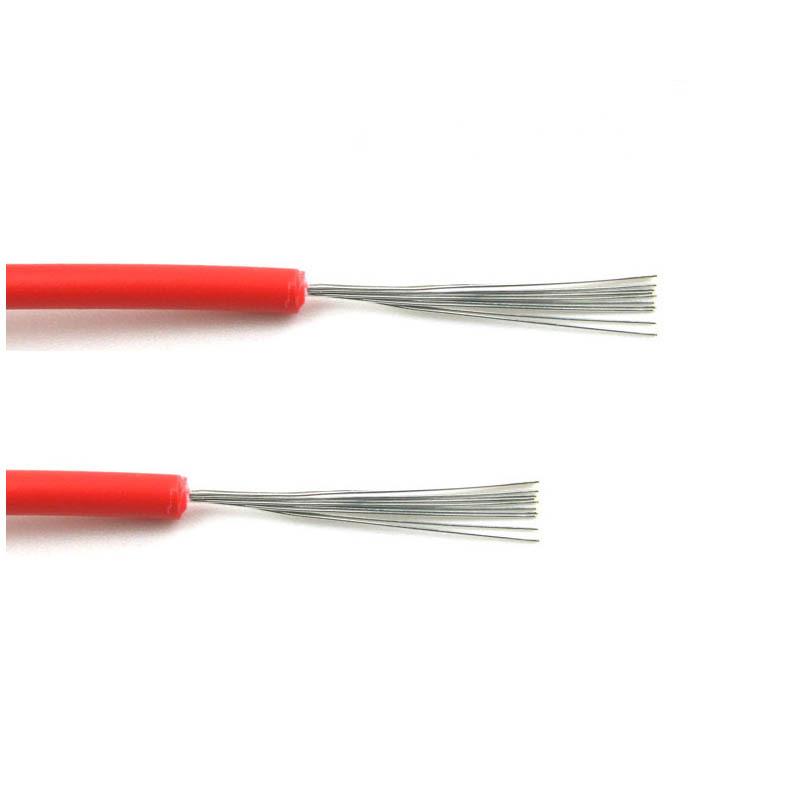

Additionally, PTFE wire is known for its flexibility and mechanical strength, allowing for easy installation and resistance to wear and tear. It is also non-flammable and self-extinguishing, ensuring fire safety in critical applications.

Applications of PTFE Wire

Given its exceptional properties, PTFE wire finds numerous applications across various industries. Some notable examples include:

1. Aerospace: PTFE wire is widely used in aircraft wiring systems due to its ability to withstand high temperatures, harsh chemicals, and vibration. It ensures reliable electrical connections and safety in critical flight operations.

2. Automotive: PTFE wire is utilized in automotive applications that require high-performance wiring, such as engine compartments, braking systems, and automotive sensors. Its resistance to heat, chemicals, and abrasion makes it ideal for these demanding environments.

3. Electronics: ptfe insulated wire is commonly found in electronic devices, including computers, telecommunication equipment, and medical devices. Its low-loss insulation properties enable efficient signal transmission and safeguard against interference.

4. Industrial: ptfe insulated wire is utilized in various industrial applications, including chemical plants, oil refineries, and power generation facilities. Its ability to resist chemicals and extreme temperatures ensures reliable and long-lasting performance.

Considerations for Choosing PTFE Wire

When selecting ptfe teflon wire for a specific application, several factors should be considered:

1. Temperature Requirements: Ensure that the wire's temperature rating aligns with the operating conditions to prevent insulation damage or failure.

2. Electrical Properties: Determine the required electrical insulation properties, such as dielectric strength, capacitance, and impedance, based on the application's needs.

3. Chemical Compatibility: Evaluate the wire's resistance to chemicals present in the environment to ensure its longevity and performance.

4. Mechanical Strength: Consider the wire's flexibility, durability, and resistance to abrasion and physical stress, especially if it will undergo frequent bending or movement.

In Conclusion

PTFE wire, utilizing PTFE as its insulation material, provides exceptional electrical, thermal, and chemical properties. Its high temperature resistance, excellent insulation characteristics, and chemical resistance make it suitable for a wide range of applications. When selecting PTFE wire, it is crucial to consider temperature requirements, desired electrical properties, chemical compatibility, and mechanical strength to ensure optimal performance and longevity.