Fluoroplastic high temperature wire is a top choice when it comes to handling the demands of extreme temperatures, chemical exposure, and mechanical stress. In this article, we’ll discuss when you should use fluoroplastic insulated wire, how it compares to other types of high temperature electrical wire, and why Dingxiang’s fluoroplastic solutions are ideal for your needs.

1. When You Need to Withstand Extreme Temperatures

One of the primary reasons to use fluoroplastic high temperature wire is its ability to handle extreme heat. Unlike standard wires that may degrade or melt under high heat, fluoroplastic materials such as PTFE (Polytetrafluoroethylene) and FEP (Fluorinated Ethylene Propylene) are specifically designed to endure temperatures ranging from -65°C to +260°C, depending on the material.In industries like aerospace, automotive, and electronics, where equipment must operate efficiently under high temperatures, fluoroplastic insulated wire offers superior performance. If your project requires wiring that needs to perform consistently in high-heat conditions, such as inside engines, ovens, or other industrial machinery, fluoroplastic wire is the go-to choice. Dingxiang provides high-quality fluoroplastic solutions that ensure long-lasting heat resistance, helping your system stay operational without the risk of wire failure due to heat.

2. When Chemical Resistance is Required

Fluoroplastic high temperature wire is known for its exceptional resistance to a wide range of chemicals, including oils, solvents, acids, and bases. This makes it an ideal choice for applications in environments where exposure to harsh chemicals is common. Standard wires may degrade quickly when exposed to corrosive substances, leading to breakdowns and safety hazards. However, fluoroplastic insulated wire is designed to resist chemical corrosion, ensuring that your electrical systems remain intact and safe, even in aggressive environments.For industries like chemical manufacturing, pharmaceuticals, and oil & gas, where wires may come into contact with aggressive substances, fluoroplastic wire is the ideal solution. Dingxiang’s fluoroplastic wire offers not only temperature resistance but also chemical protection, ensuring that your equipment continues to operate safely and efficiently without the risk of wire degradation.

3. When Flexibility and Durability are Needed

Another significant benefit of fluoroplastic high temperature wire is its flexibility and durability. Despite its ability to withstand extreme heat and chemical exposure, it remains flexible enough to be used in complex wiring systems. Whether your application requires intricate wiring in tight spaces or long-lasting durability to resist mechanical stress, fluoroplastic insulated wire is a versatile choice.For applications in robotics, military equipment, or high-performance electronics, where wiring needs to be both flexible and resilient, fluoroplastic high temperature wire is perfect. This flexibility, combined with its resistance to wear and tear, ensures that wires continue to function smoothly without breaking down under physical stress. Dingxiang's fluoroplastic wires are engineered for durability, providing excellent performance over time, even in the most demanding conditions.

4. When You Require Electrical Insulation

Electrical insulation is another critical consideration in many high-temperature applications. Fluoroplastic insulated wire offers excellent electrical insulation properties, ensuring that your electrical systems operate safely without the risk of short circuits or electrical fires. Its dielectric strength is far superior to many other insulating materials, allowing it to perform well in both high-voltage and high-temperature settings.For projects where electrical safety is paramount—such as in power generation, industrial machinery, or electronics—choosing fluoroplastic high temperature wire can prevent the risk of electrical failures. The superior insulating properties of fluoroplastic material ensure the integrity of your wiring systems, even under intense operational conditions. Whether you are working with high temperature electrical wire for industrial machinery or wiring for critical electronics, Dingxiang's fluoroplastic wires offer reliable insulation and protection.

5. When You Need Low Maintenance and Longevity

In many industrial settings, downtime is costly, and the maintenance of electrical wiring systems can be time-consuming and expensive. Fluoroplastic high temperature wire is highly durable and has a long lifespan, which significantly reduces the need for frequent maintenance or replacement. This low-maintenance aspect makes it a cost-effective solution for projects that require longevity and reliability.Dingxiang’s fluoroplastic wire products are designed with this longevity in mind. The wire's resistance to high temperatures, chemicals, and physical wear means you won’t have to worry about replacing wires regularly. This saves both time and money, making it an attractive option for large-scale industrial systems, automotive applications, or any project where reliability over time is critical.

6. When You Need Compliance with Industry Standards

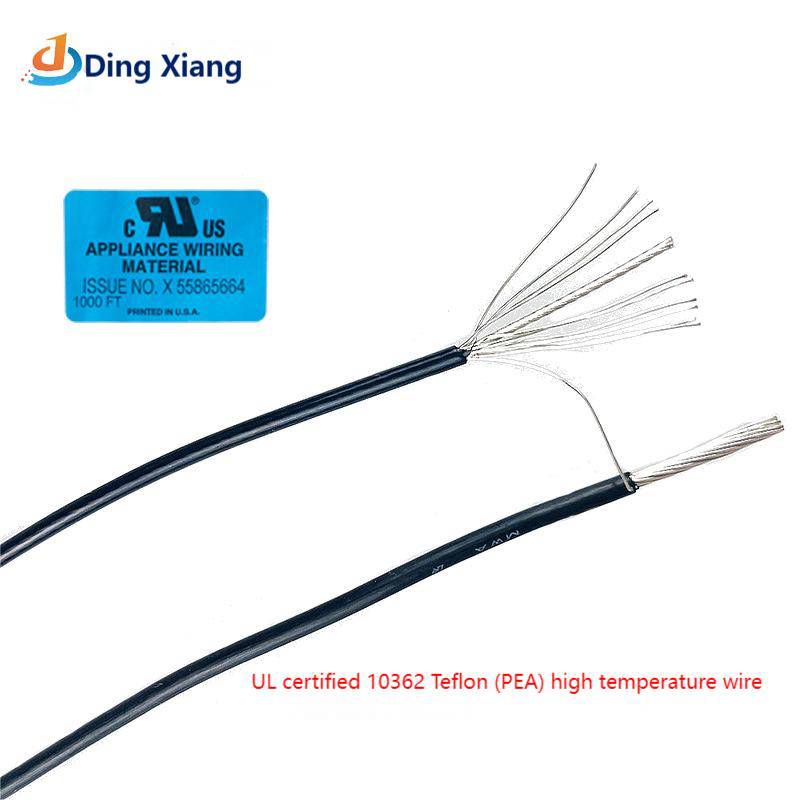

Certain industries have strict safety standards and regulations, especially in fields like aerospace, military, and medical applications. Fluoroplastic high temperature wire is often manufactured to meet these stringent requirements, ensuring that it complies with industry standards for safety and performance.If your project needs to meet regulatory compliance for high-temperature or high-performance environments, choosing fluoroplastic insulated wire from Dingxiang ensures that your wiring solutions are up to code. Whether you’re building high-tech equipment for the aerospace industry or designing electrical systems for industrial applications, using fluoroplastic wire guarantees that your systems adhere to the necessary safety and performance standards.

Conclusion:

There are several key reasons why fluoroplastic high temperature wire is the ideal choice for certain high-performance projects. From its ability to withstand extreme temperatures and resist chemicals to its excellent electrical insulation properties and long lifespan, fluoroplastic wire offers numerous benefits in environments that demand durability and reliability. Dingxiang's high-quality fluoroplastic insulated wire is designed to meet the most demanding specifications, ensuring that your project operates smoothly and safely over time. Whether you're working in manufacturing, aerospace, or electronics, fluoroplastic high temperature wire is the smart choice for ensuring your electrical systems are built to last.