When selecting wiring for your next project, it’s crucial to choose a wire that meets your specific requirements for durability, flexibility, and high-performance. UL3512 soft silicone wire is a leading choice for a wide range of applications due to its unique properties and superior quality. In this article, we’ll explore why you should consider UL3512 soft silicone wire for your next project and how it can improve both the reliability and longevity of your electrical systems.

What Is UL3512 Soft Silicone Wire?

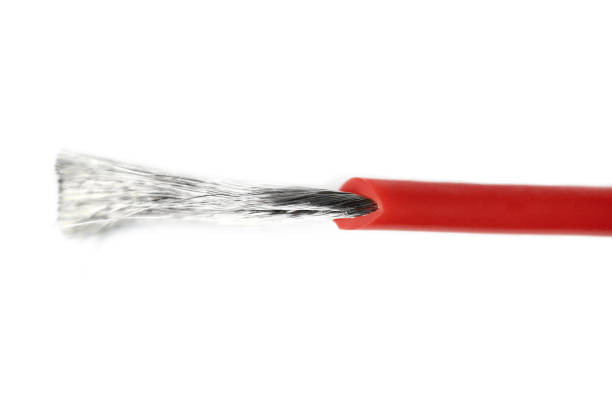

UL3512 soft silicone wire is a high-quality wire insulated with silicone rubber, designed for flexible and high-performance applications. It’s UL-certified, meaning it meets stringent safety and quality standards for electrical wiring. The wire’s soft silicone insulation makes it particularly flexible, allowing it to be bent and shaped easily without compromising its integrity or performance.

Key Benefits of UL3512 Soft Silicone Wire

1. High Temperature Resistance

One of the standout features of UL3512 soft silicone wire is its exceptional heat resistance. Unlike standard PVC wires, which can melt or degrade at high temperatures, silicone insulation can withstand temperatures ranging from -60°C to +200°C. This makes UL3512 wire an excellent choice for high-temperature environments, such as in automotive, aerospace, and industrial equipment.

2. Superior Flexibility

Another major advantage of UL3512 soft silicone wire is its flexibility. Silicone rubber is naturally soft, which allows the wire to bend and twist without risk of cracking or breaking. This flexibility is especially beneficial for applications where the wire needs to move or be routed through tight spaces, like in robotics, machinery, or other dynamic environments.

3. Durability and Longevity

UL3512 soft silicone wire is known for its long lifespan. Its silicone insulation provides resistance to wear, abrasion, and aging, even when exposed to harsh conditions like moisture, UV light, and chemicals. This makes it highly reliable in demanding industries like automotive, marine, and manufacturing, where exposure to tough conditions is common.

4. Electrical Safety and Performance

The wire’s insulation also enhances electrical safety. Silicone is an excellent electrical insulator, preventing accidental short circuits or exposure to live wires. It also ensures the wire maintains excellent conductivity over time, even under extreme conditions, which is critical for systems that rely on stable and consistent performance.

5. Environmental Resistance

Silicone rubber has natural resistance to environmental factors like ozone, UV radiation, and humidity. These characteristics make UL3512 soft silicone wire ideal for outdoor or extreme environment applications where other wires might deteriorate quickly. Whether it’s exposed to sunlight or used in wet conditions, this wire won’t degrade or lose its protective qualities easily.

Ideal Applications for UL3512 Soft Silicone Wire

Due to its impressive features, UL3512 soft silicone wire is perfect for a wide range of applications, including:

Automotive Industry: UL3512 wire is used in vehicles for high-temperature and flexible wiring in engine compartments, where traditional wires can fail.

Aerospace: Aircraft and spacecraft systems demand highly flexible, durable, and heat-resistant wires, which UL3512 excels at providing.

Electronics: Many electronic devices, especially those that require durable and flexible wiring, benefit from the use of UL3512 wire.

Medical Equipment: The reliability and flexibility of UL3512 soft silicone wire make it a great choice for medical devices, where performance and safety are critical.

Industrial Machinery: For factory automation, robotics, and other machinery applications, this wire provides flexibility and durability in harsh conditions.

Why Choose UL3512 Soft Silicone Wire Over Other Options?

When compared to other types of wires, UL3512 soft silicone wire offers several distinct advantages:

Better Temperature Resistance: Unlike PVC or thermoplastic wires, UL3512 can handle a much wider range of temperatures without degrading.

Improved Flexibility: The soft silicone insulation makes the wire easier to manipulate, especially in tight or moving spaces, compared to more rigid wires.

Longer Lifespan: The durable silicone rubber ensures that UL3512 wire lasts longer than standard wires, reducing the need for replacements or maintenance.

Higher Safety Standards: UL3512 meets UL certification standards, providing added assurance of safety and reliability.

How to Choose the Right UL3512 Soft Silicone Wire for Your Needs

Choosing the right UL3512 soft silicone wire depends on several factors, including the application, required temperature range, and environmental conditions. Here are a few things to consider:

Temperature Range: Make sure the wire’s temperature rating matches the environment it will be exposed to.

Wire Gauge: Choose the correct gauge of wire based on the current requirements of your electrical system.

Flexibility Needs: If the wire will be subjected to frequent movement or bending, ensure you select a wire that can handle that level of flexibility.

UL3512 soft silicone wire offers a unique combination of heat resistance, flexibility, durability, and safety that makes it ideal for a variety of high-performance applications. Whether you're working in automotive, aerospace, medical, or industrial fields, this wire will enhance the reliability and longevity of your electrical systems. By choosing UL3512 soft silicone wire, you're investing in a product that not only meets industry standards but also provides superior performance in the most demanding environments.