In the fast-paced world of industrial manufacturing, efficiency and reliability are crucial. One key component that ensures both is high temperature Teflon wire. Known for its exceptional heat resistance, chemical stability, and mechanical durability, this specialized wire is increasingly becoming an essential part of industrial equipment. In this article, we will discuss how high temperature Teflon wire improves industrial equipment performance and why it is considered a game-changer for industries worldwide.

1. Unmatched Heat Resistance

Industrial environments often involve machinery that operates under extreme temperatures. From furnaces in manufacturing plants to engines in automotive systems, equipment frequently needs wiring that can withstand intense heat. High temperature Teflon wire is built to handle temperatures ranging from -200°C to +260°C, far exceeding the capabilities of standard wires. This remarkable heat resistance allows high temperature Teflon wire to maintain performance in high-heat areas where conventional wires would melt or degrade. For industries like steel manufacturing, petrochemicals, or power generation, the ability to use this wire in high-temperature environments ensures that electrical systems remain reliable and operational without compromising safety or efficiency.

2. Chemical Resistance for Harsh Environments

Many industries, such as pharmaceuticals, food processing, and chemical production, expose equipment to harsh chemicals that can damage or corrode standard wiring. High temperature Teflon wire, however, stands out due to its exceptional resistance to chemicals, acids, solvents, and other corrosive substances. Its inert nature prevents degradation even when exposed to some of the most aggressive chemicals. By utilizing high temperature Teflon wire in electrical systems, industries can avoid frequent breakdowns caused by chemical reactions, ensuring smoother and uninterrupted operations. This chemical resistance is particularly valuable in environments where equipment is constantly exposed to corrosive agents, allowing for safer, more reliable machinery performance.

3. Enhanced Electrical Insulation

In any industrial setting, electrical safety is paramount. The insulation properties of high temperature Teflon wire make it a critical component in safeguarding electrical systems. Teflon’s high dielectric strength provides excellent electrical insulation, reducing the risks of electrical short circuits or accidental discharges that could potentially lead to fires or equipment failures.

The robust insulation of high temperature Teflon wire ensures that electrical currents are safely contained within the system, preventing issues like electrical shock and power loss. This level of safety not only protects workers but also reduces maintenance costs and prevents downtime due to electrical faults.

4. Durability Under Mechanical Stress

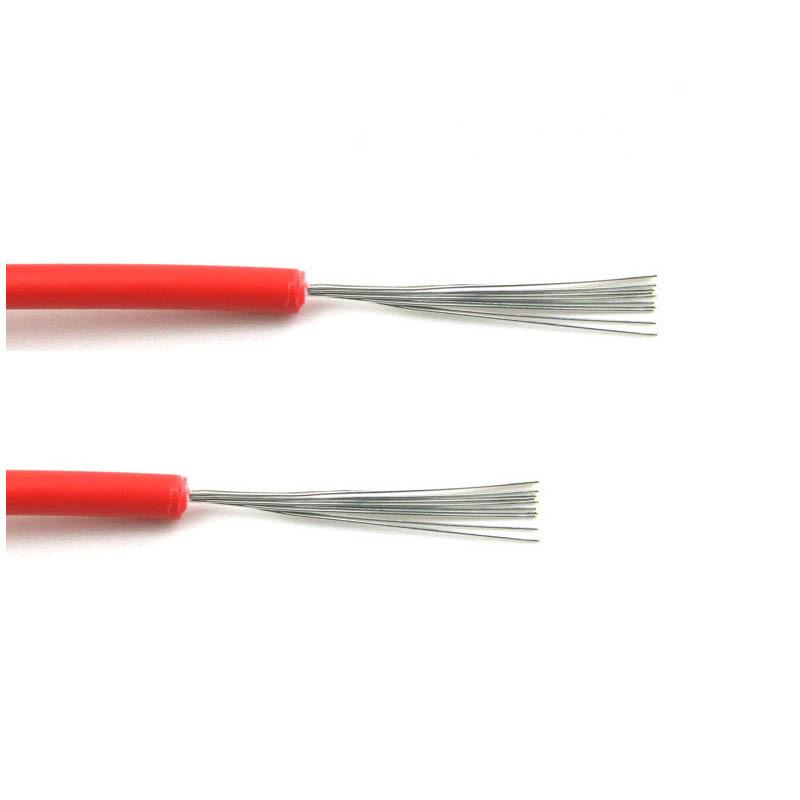

Industries like automotive manufacturing, aerospace, and robotics require components that can withstand continuous movement and mechanical stress. High temperature Teflon wire excels in such environments due to its flexibility and durability. It maintains its structural integrity even in high-vibration areas, such as in robotic arms, engines, or conveyor systems. This durability ensures that the wire won’t crack, fray, or fail due to mechanical movement, allowing equipment to operate at peak efficiency. Moreover, the flexibility of Teflon wire enables easy installation in areas where space is limited or where complex routing is necessary.

5. Increased Efficiency and Reduced Downtime

When electrical systems fail, it can lead to significant downtime, resulting in lost productivity and high repair costs. High temperature Teflon wire mitigates this risk by offering a long-lasting, reliable solution that reduces the likelihood of breakdowns. Its resistance to extreme conditions ensures that electrical connections remain intact, even under challenging circumstances.

By reducing the chances of wire failures, teflon high temperature cable plays a pivotal role in maintaining equipment uptime. The wire’s ability to perform consistently without degradation leads to enhanced operational efficiency and reduced maintenance costs over the long term. In turn, this keeps production lines running smoothly and minimizes costly delays.

6. Cost-Effectiveness Through Longevity

While high temperature Teflon wire may have a higher initial cost than traditional wiring options, its longevity and durability make it a cost-effective choice in the long run. The wire’s resistance to heat, chemicals, and mechanical stress means it lasts longer, reducing the need for frequent replacements. This translates to fewer maintenance interventions and lower operational costs over time.

Additionally, the reduction in downtime and the increased efficiency of machinery result in improved productivity, which contributes to a higher return on investment. For industries that rely on the continuous operation of their equipment, the durability of high temperature Teflon wire makes it a wise and economical investment.

7. Versatility Across Different Industries

High temperature Teflon wire is versatile and used in a wide range of industries. From aerospace to automotive, from chemical processing to renewable energy, this wire plays an essential role in various sectors. Its ability to withstand heat, chemicals, and mechanical stress makes it ideal for applications ranging from engine control systems in cars to critical wiring in aircraft and solar energy systems.

For example, in the automotive industry, high temperature Teflon wire is often used in ignition systems and under-the-hood applications where exposure to high heat and vibration is constant. Similarly, in renewable energy systems, such as solar and wind power, this wire ensures that electrical components continue to function efficiently in harsh weather conditions.

8. Why High Temperature Teflon Wire is Indispensable

With the growing demand for high-performance and high-reliability industrial equipment, high temperature Teflon wire has become indispensable in many sectors. Its heat resistance, chemical stability, electrical insulation, mechanical durability, and longevity all contribute to its status as a top choice for industries that require dependable, long-lasting electrical components.

As industrial machinery continues to evolve, the need for more advanced and durable wiring solutions becomes more critical. High temperature Teflon wire not only meets these demands but exceeds them, ensuring that equipment can operate under the most challenging conditions while maintaining optimal performance.

High temperature Teflon wire is a crucial element in improving the performance of industrial equipment. Its ability to withstand extreme temperatures, resist harsh chemicals, provide superior electrical insulation, and endure mechanical stress makes it an ideal choice for industries ranging from aerospace to energy. By offering enhanced durability, reducing downtime, and improving efficiency, high temperature Teflon wire ensures that industrial systems perform at their best while minimizing maintenance costs. As industries continue to face more demanding environments, high temperature Teflon wire will remain a vital component in achieving reliable, long-lasting equipment performance.