When it comes to selecting the right wire for electrical applications, there are a multitude of options available on the market. Among these, UL3239 Silicone Wire stands out as a unique and superior choice for various reasons. This article will delve into what makes UL3239 Silicone Wire different from other types of wire, the role of UL3239 Silicone Wire Suppliers, and the importance of choosing a reputable UL3239 Silicone Wire Manufacturer.

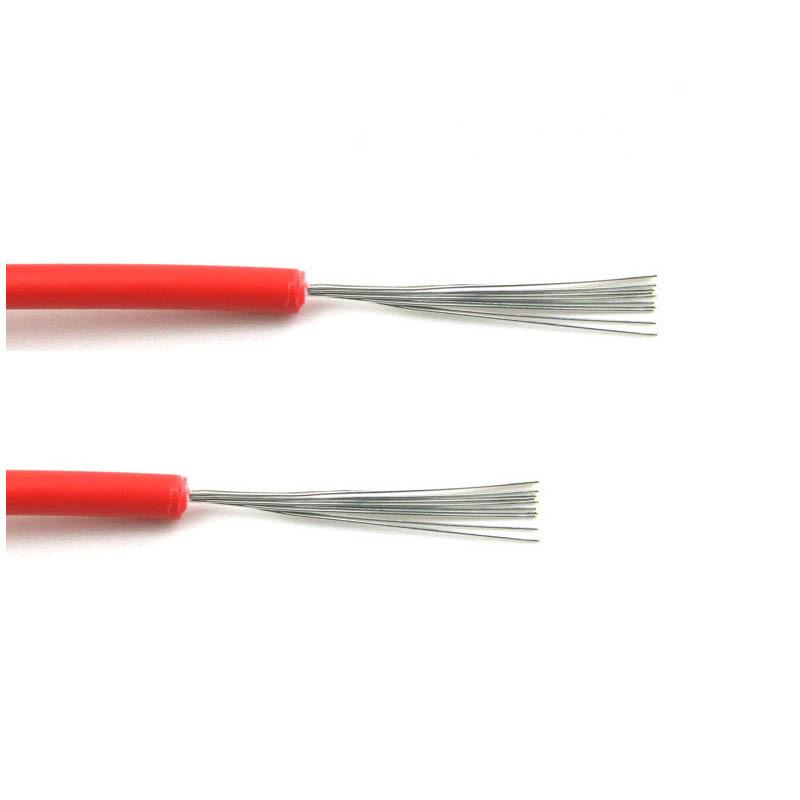

UL3239 Silicone Wire is a type of high-temperature wire that is made from a silicone rubber insulation layer and a fiberglass braided reinforcement. It is designed to withstand continuous operating temperatures of up to 200°C (392°F), making it ideal for applications where high heat is a factor. The 'UL' in UL3239 refers to Underwriters Laboratories, a global safety certification company, indicating that this wire has met stringent safety standards.

Key Features of UL3239 Silicone Wire

- High-Temperature Resistance: Unlike many other types of wire that may degrade or melt under high heat, UL3239 Silicone Wire maintains its integrity and performance.

- Silicone Insulation: The silicone rubber insulation provides excellent electrical insulation and resistance to environmental factors such as moisture, UV radiation, and oxidation.

- Fiberglass Braided Reinforcement: This adds strength and flexibility, allowing the wire to withstand mechanical stress and resist abrasion.

- Chemical Resistance: UL3239 Silicone Wire is resistant to a wide range of chemicals, making it suitable for harsh environments.

- Flexibility: Despite its high-temperature capabilities, this wire remains flexible, allowing for easier installation in tight spaces.

Applications of UL3239 Silicone Wire

UL3239 Silicone Wire is used in a variety of applications due to its unique properties:

- Automotive and Aerospace: For engine wiring, where high temperatures are common.

- Medical Equipment: In devices that require sterilization at high temperatures.

- Industrial Machinery: For applications involving moving parts or high-heat environments.

- Electrical Appliances: In appliances that generate heat, such as ovens and dryers.

- Cable Assemblies: For custom wiring solutions that need to withstand high temperatures.

The Role of UL3239 Silicone Wire Suppliers

UL3239 Silicone Wire Suppliers play a crucial role in connecting manufacturers and end-users. They provide a range of services, including:

- Stock Availability: Ensuring a steady supply of UL3239 Silicone Wire to meet demand.

- Custom Orders: Offering the ability to order specific lengths or configurations of the wire.

- Technical Support: Providing expertise and advice on the best applications for UL3239 Silicone Wire.

- Quality Assurance: Working with manufacturers to ensure that the wire meets all safety and performance standards.

Selecting a reputable UL3239 Silicone Wire Manufacturer is essential to ensure that you receive a high-quality product. Here are some factors to consider:

- Certifications: Look for manufacturers with UL certification and other relevant industry certifications.

- Quality Control: A good manufacturer will have robust quality control processes in place.

- Experience: Choose a manufacturer with a proven track record and experience in the industry.

- Customization Capabilities: Some applications may require custom-made wires, so look for a manufacturer that can accommodate these needs.

- Customer Reviews: Check customer reviews and testimonials to gauge the manufacturer's reliability and product quality.

UL3239 Silicone Wire offers a range of benefits that set it apart from other types of wire, making it an excellent choice for high-temperature applications and environments where durability and safety are paramount. When sourcing this wire, it's important to work with a reliable UL3239 Silicone Wire Supplier and UL3239 Silicone Wire Manufacturer to ensure that you receive a product that meets all necessary standards and performs as expected. By understanding the unique properties of UL3239 Silicone Wire and the role of suppliers and manufacturers, you can make an informed decision for your electrical applications.